Production

Innovative technology

Our 3-4-5 axis CNC machines

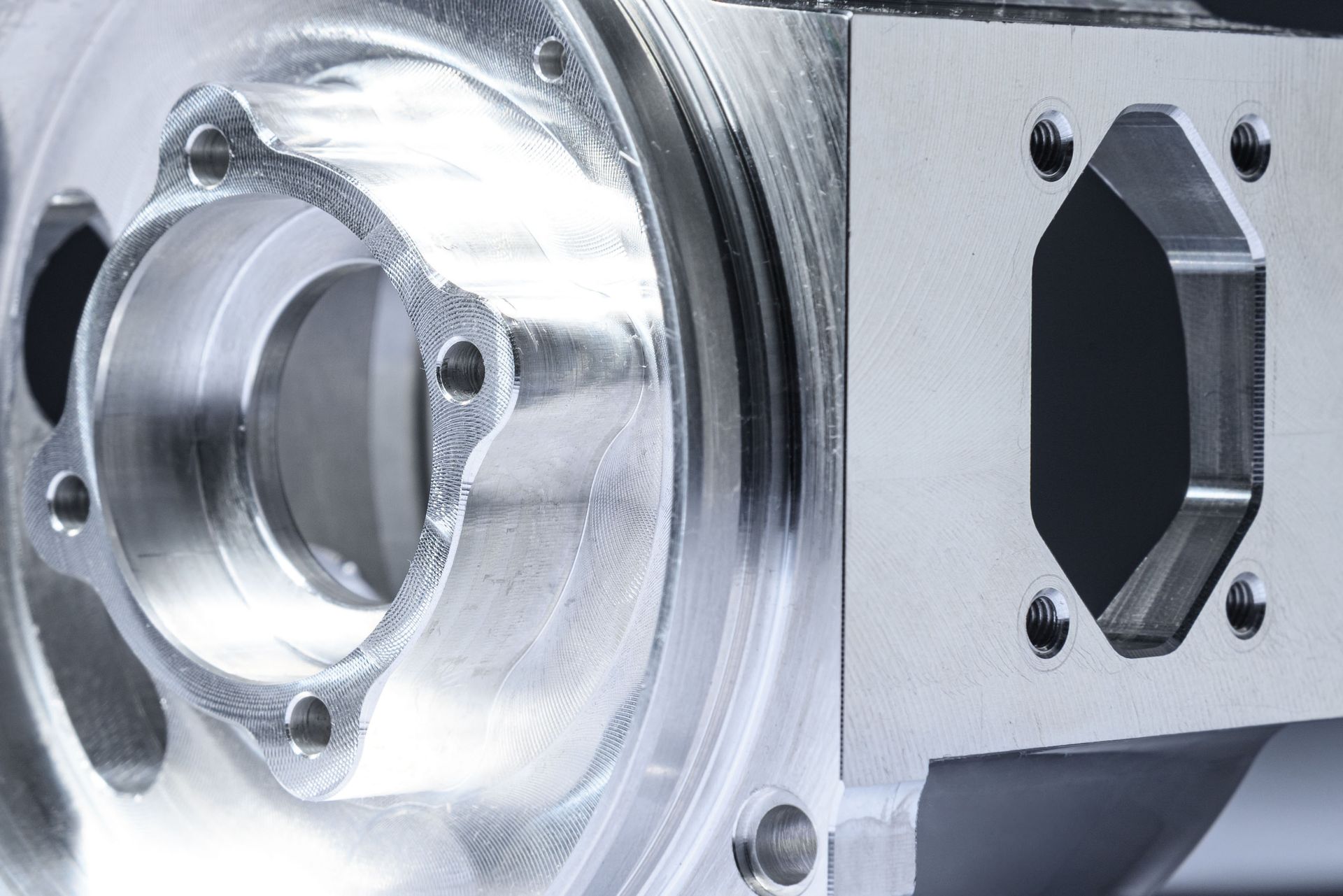

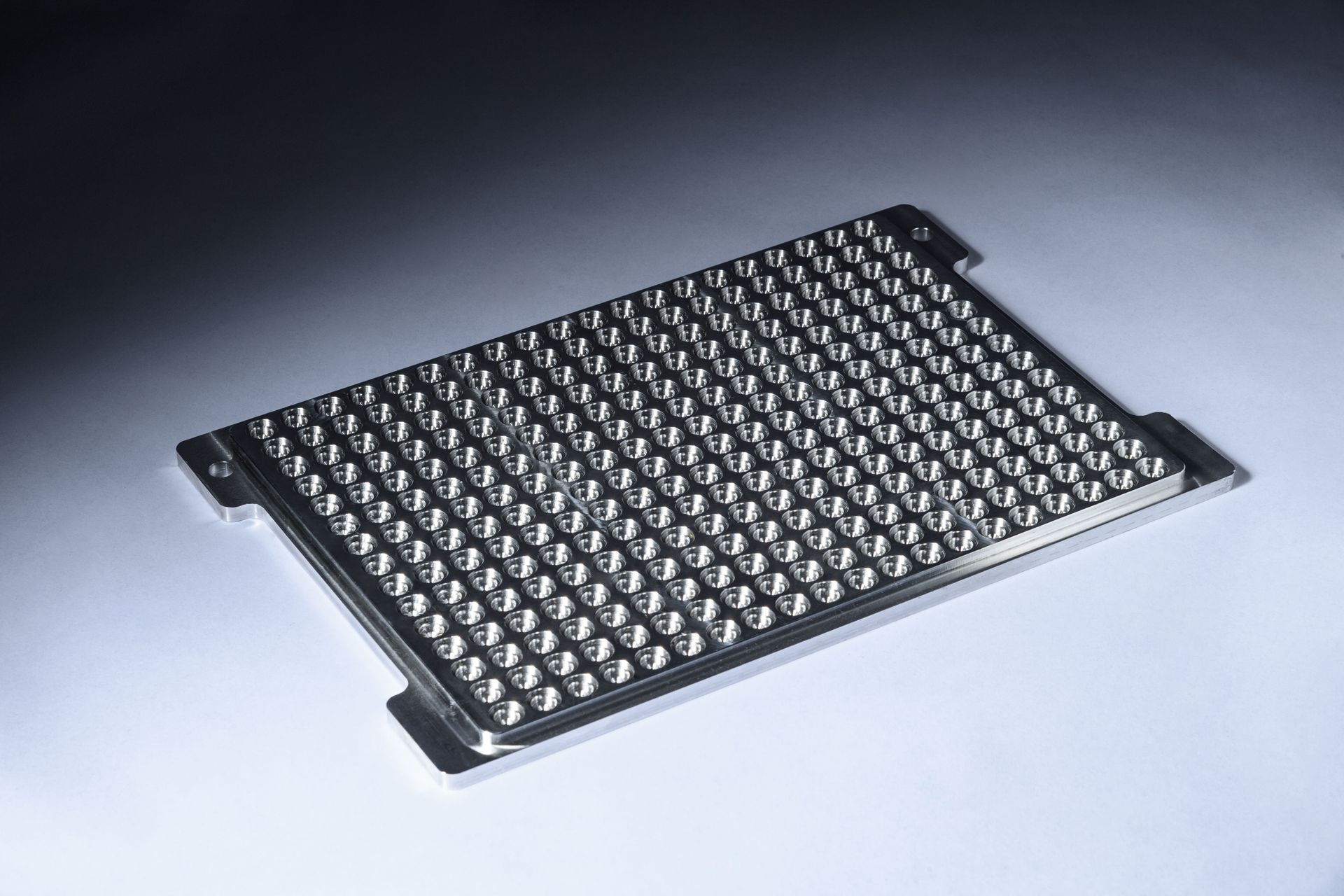

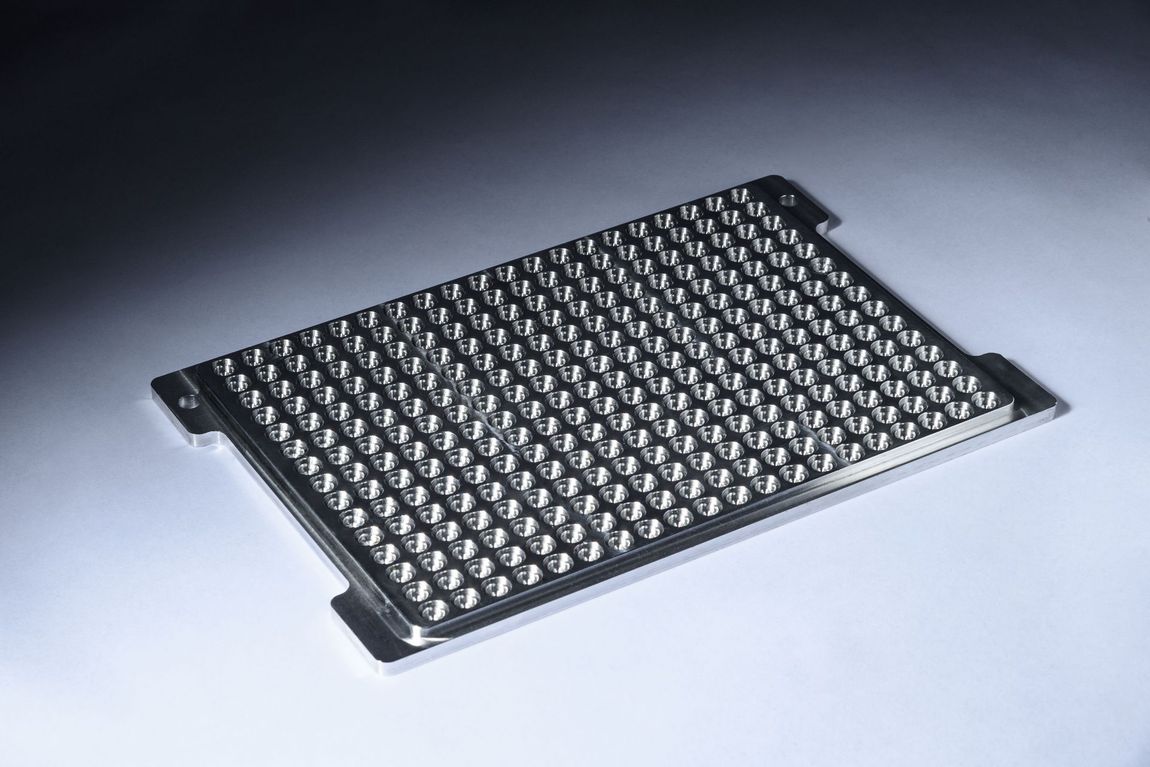

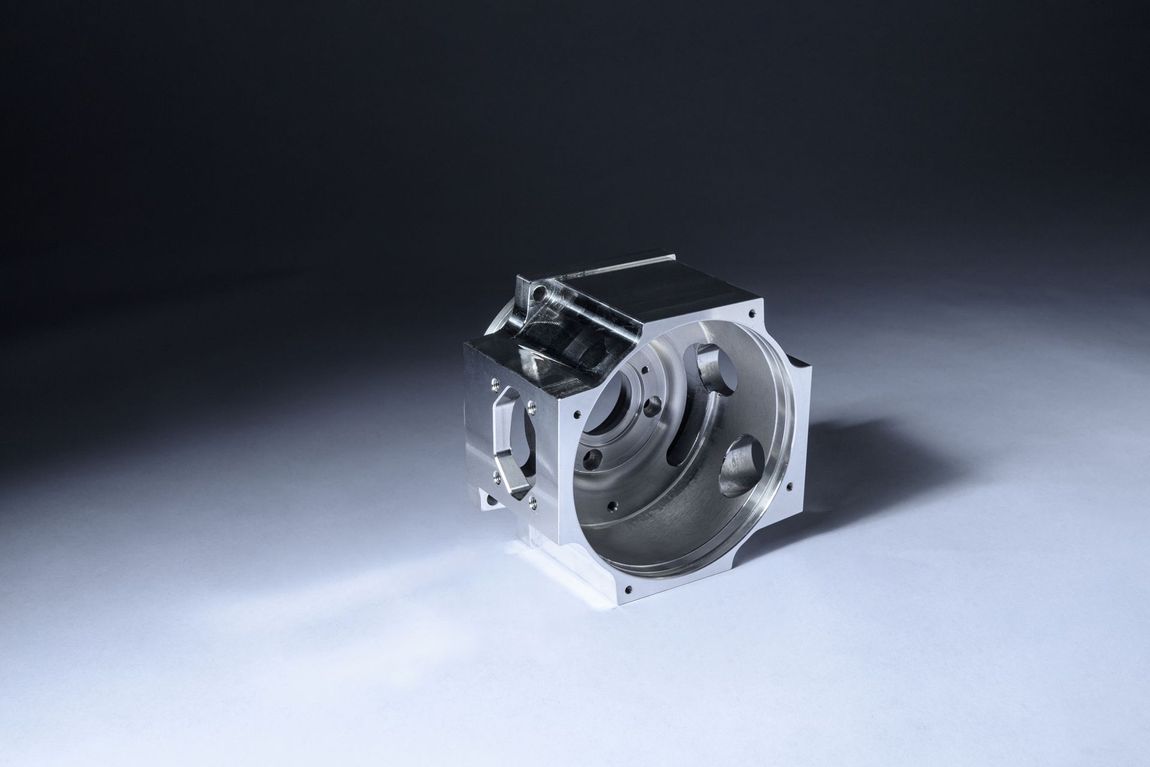

GBM was among the first companies to implement the Industry 4.0 project to network all production phases and machinery. With customised management software and an automated tool warehouse which minimises the machines' set-up time, each order is sent to the production department and checked in real time until delivery. Each piece is made with CNC machines with 3, 4 and 5 axes, capable of complex mechanical machining and absolute precision, guaranteed by a modern measurements room for scrupulous control over the production cycle. This room verifies the tolerances indicated in the technical drawing. GBM also has an assembly department for the assembly and testing of the finished and processed product.

Titolo diapositiva

Scrivi qui la tua didascaliaPulsanteTitolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Slide title

Write your caption hereButton

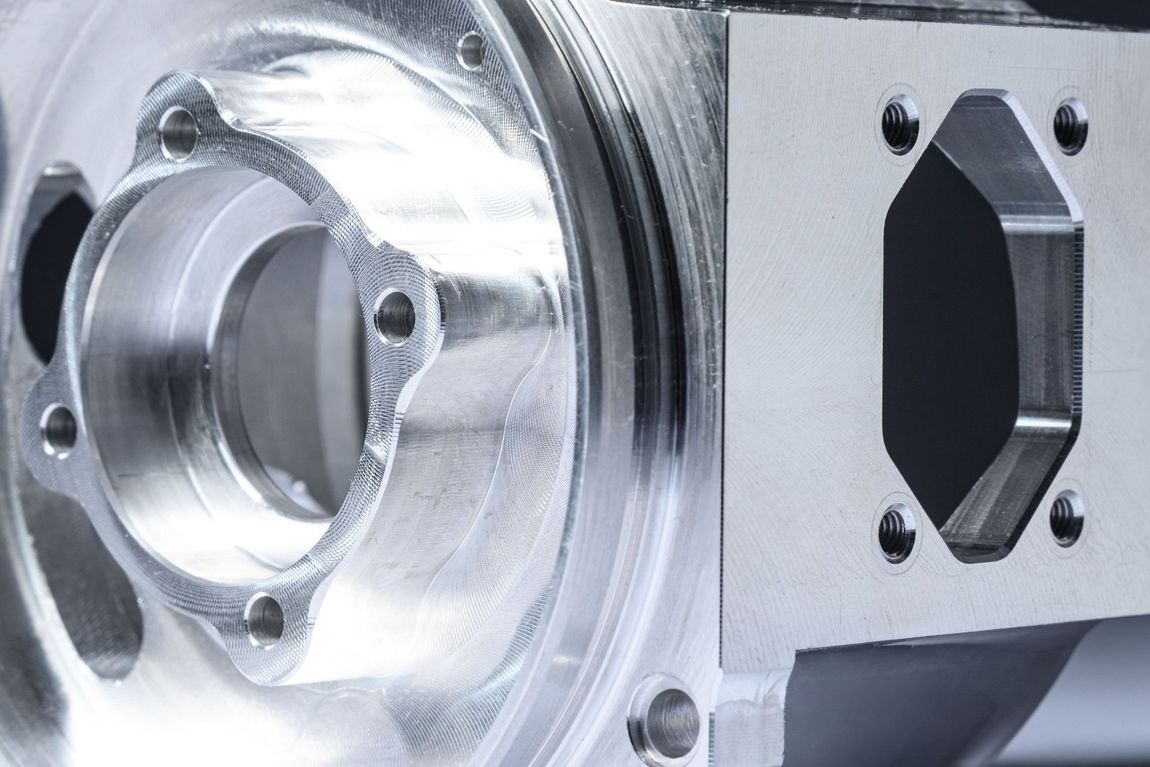

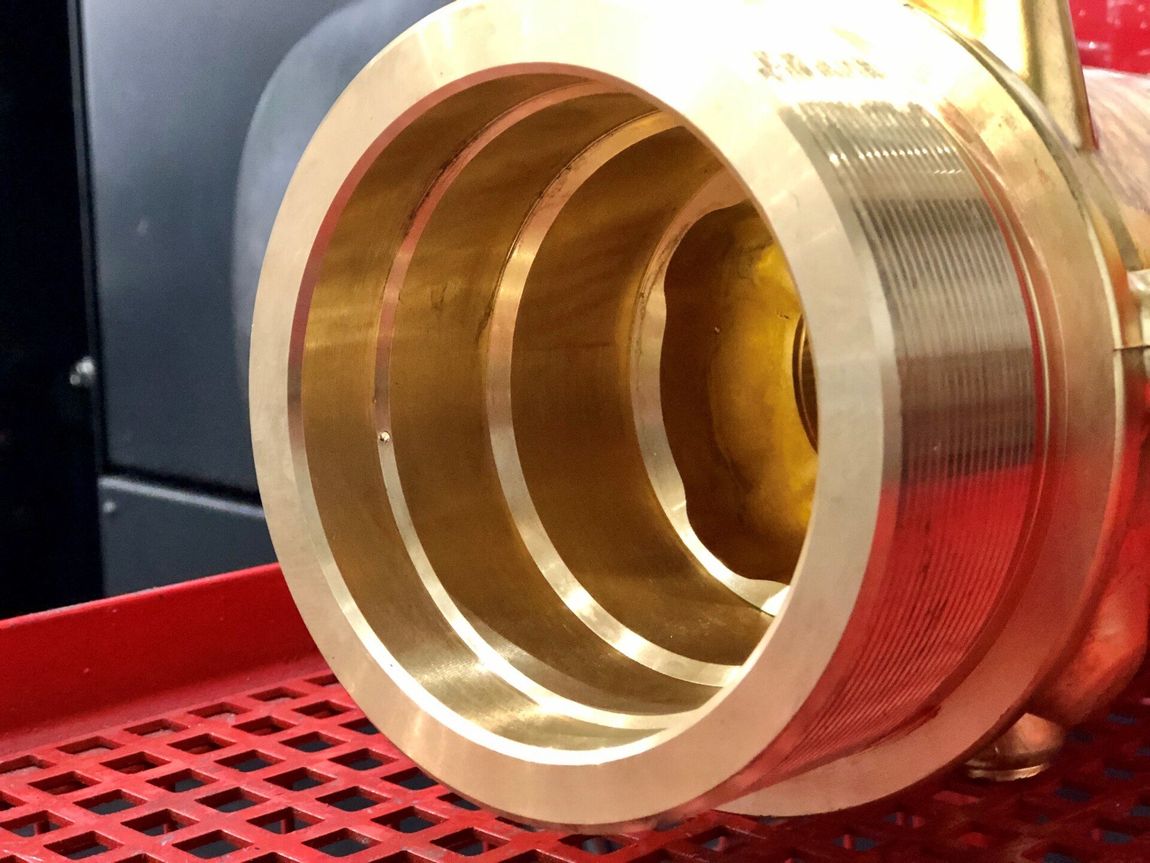

Turning

GBM performs turning from round bar with ø65 passage on aluminium and its alloys, aluminium die-castings, brass, ecobrass and steel. This process takes place on multitasking turning centres by milling, boring and threading on the machine. All following the technical drawing and specifications provided by the customer.

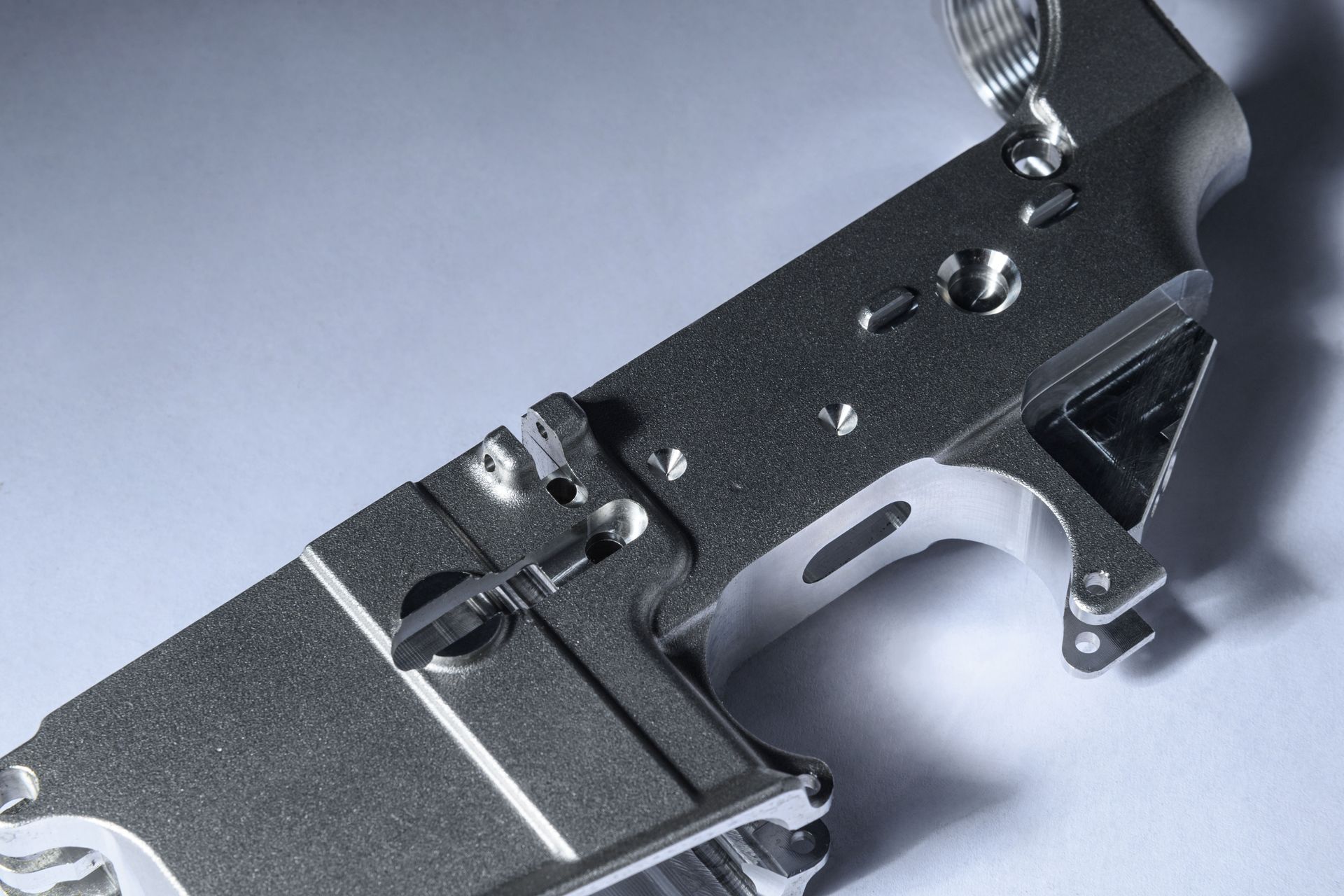

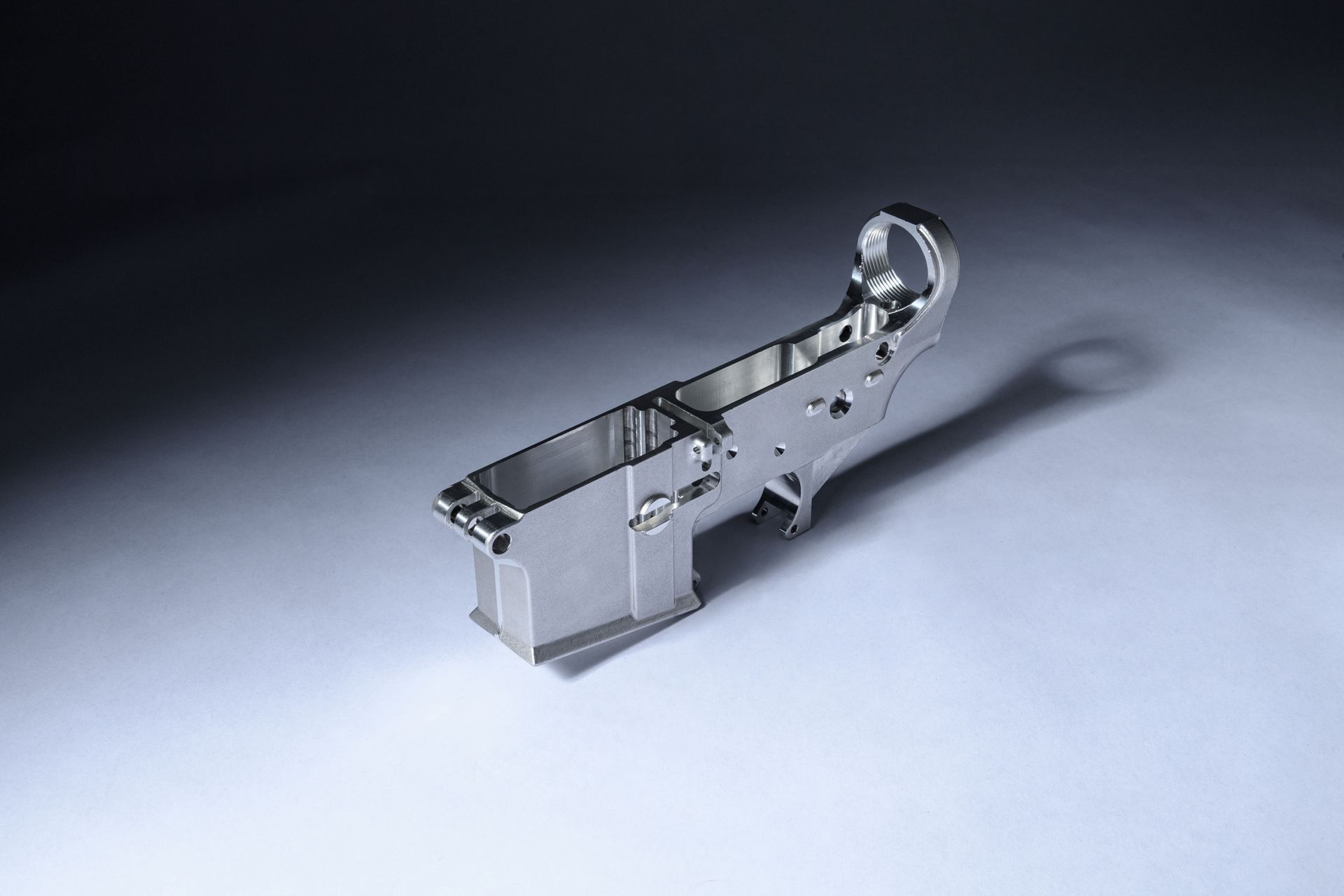

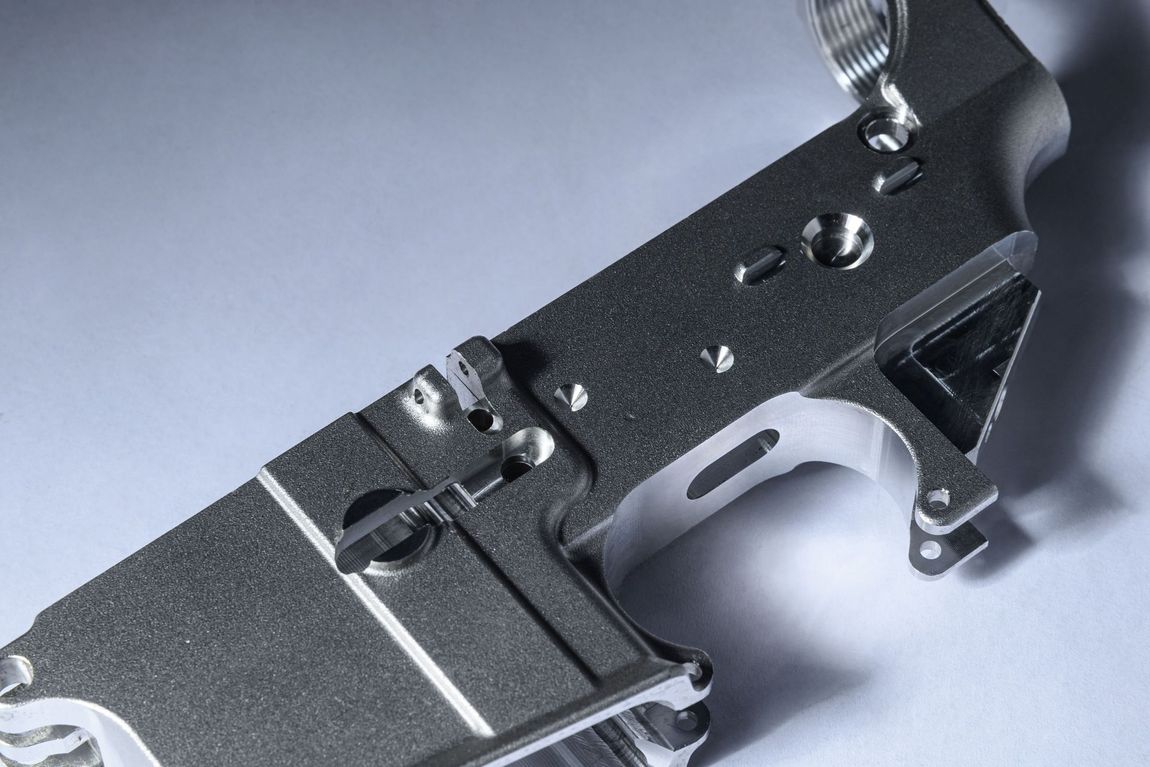

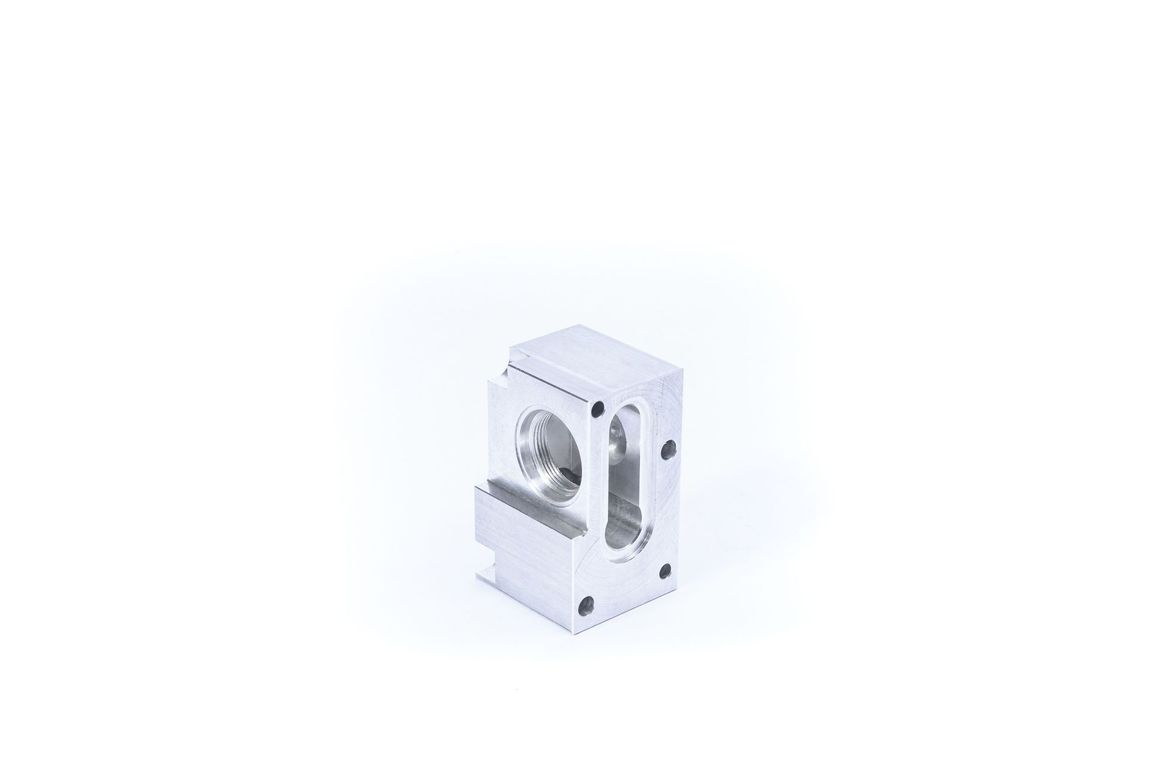

Milling

To meet every need in the engineering sector, GBM has 3/4/5 axis machining centres for small, medium and large-scale production.

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Slide title

Write your caption hereButton

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Slide title

Write your caption hereButton

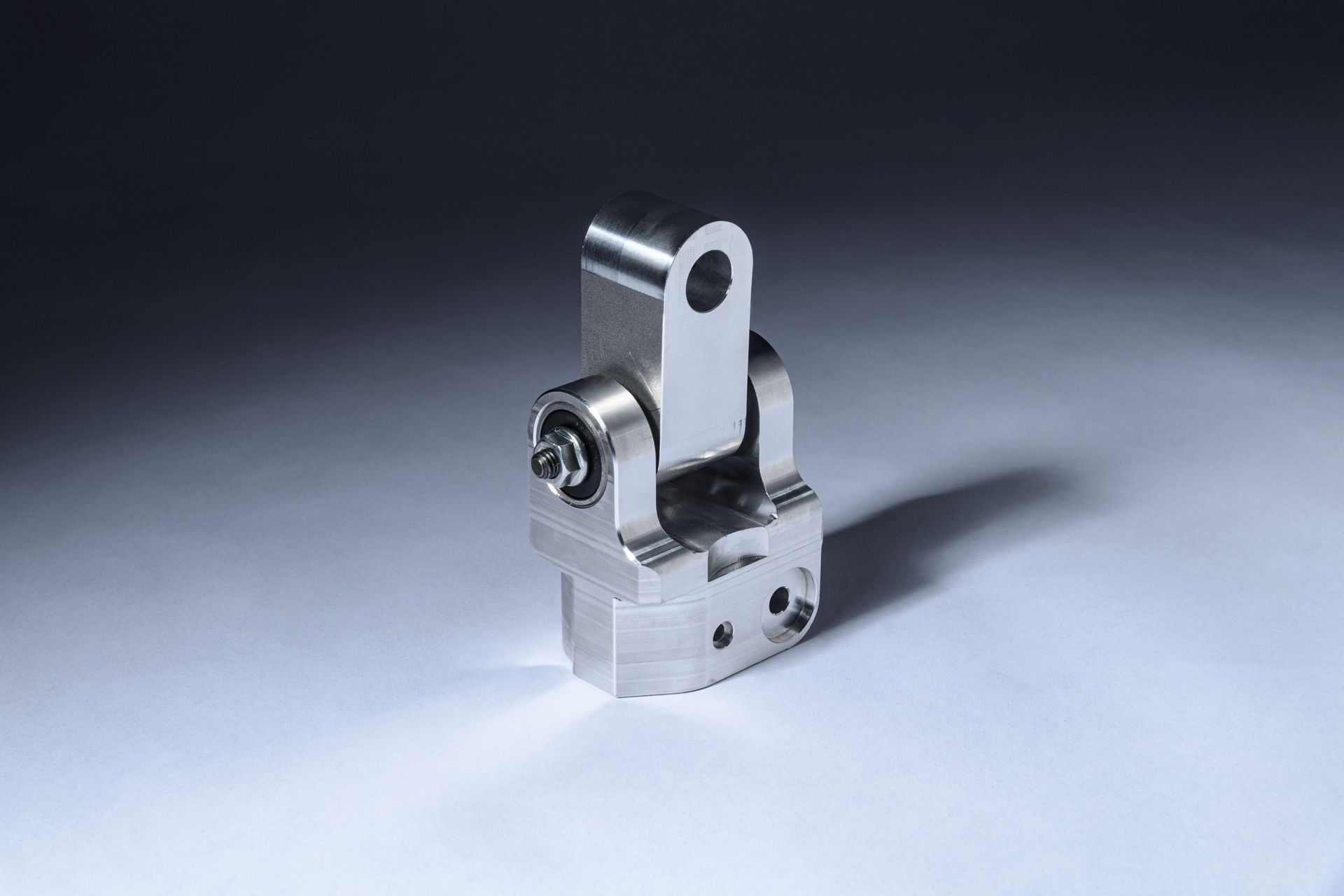

Assembly

In the production department, we have an area dedicated to visual sorting for the manual and /or automatic assembly of components and products with technical drawings for the final customer.

Customer service

Respect for deadlines and complete customer service are essential values in a GBM quality management system:

technical consultancy;

feasibility analysis with simulations to establish any critical issues;

production cost analysis;

planning and optimisation of production processes;

batch traceability;

procurement and storage of raw materials;

agreed delivery schedule.

Slide title

Write your caption hereButton

CONTACT

+39 0364 880271

OPENING HOURS

- Mon - Fri

- - -

- Sat - Sun

- Closed

VAT Reg. No.: 03106500980 | Legal information

| Privacy and Cookie Policy